Benefits of Stainless Steel Casting

- Tight Tolerance

- Very Smooth Surface Finish

- Efficient Production

- Design & Casting Versatility

- Material Variety

- Affordable Tooling

- Reliable Process

- Repeatability

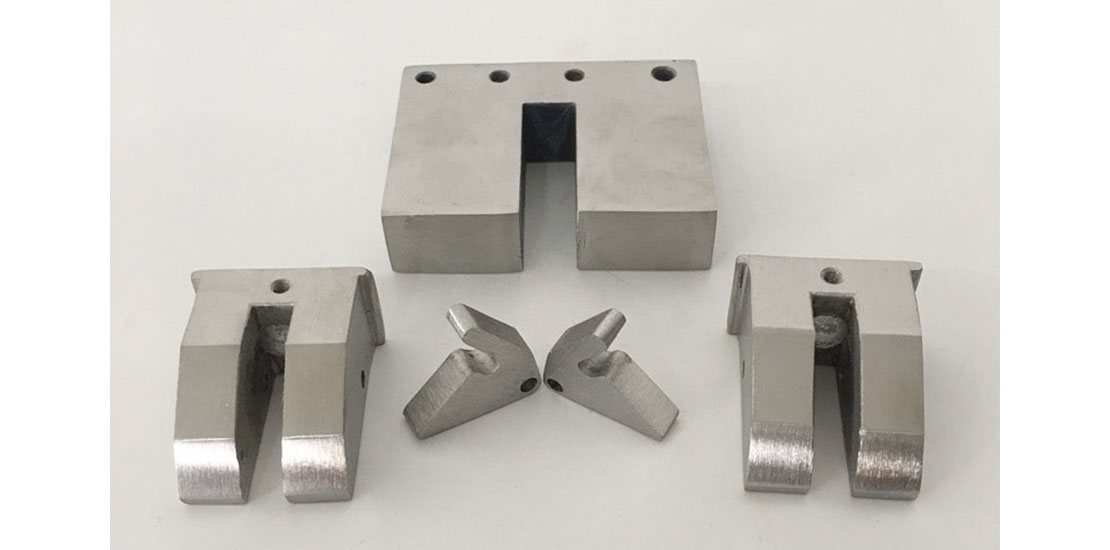

Being a reputed manufacturer in India, we use different types of steels during our casting process that includes alloy steel, SS (stainless steel) and more. Our (Stainless Steel) SS Castings are well known in the industry for their strength, durability and efficiency. The most application areas of our steel castings include gears, valve bodies, engine parts, forging presses, pump castings, and hydroelectric turbine wheels etc.

At Bhagwati Metal Industries, we work with stainless steel which contains nickel, chromium, low carbon stainless, and molybdenum. We also work with high-quality stainless which is specifically designed for medical equipment, aircraft, railways, constructions, automotive and chemical industries. We can also provide our clients with preceded casting services with machining and in-house finishing.

Grades of Stainless Steel

- ASTM / ASME SA 304, 304L, 316, 316L, 310, 310S, 410